Isibambi Sebhulashi Eliphansi R057-02

Incazelo Yomkhiqizo

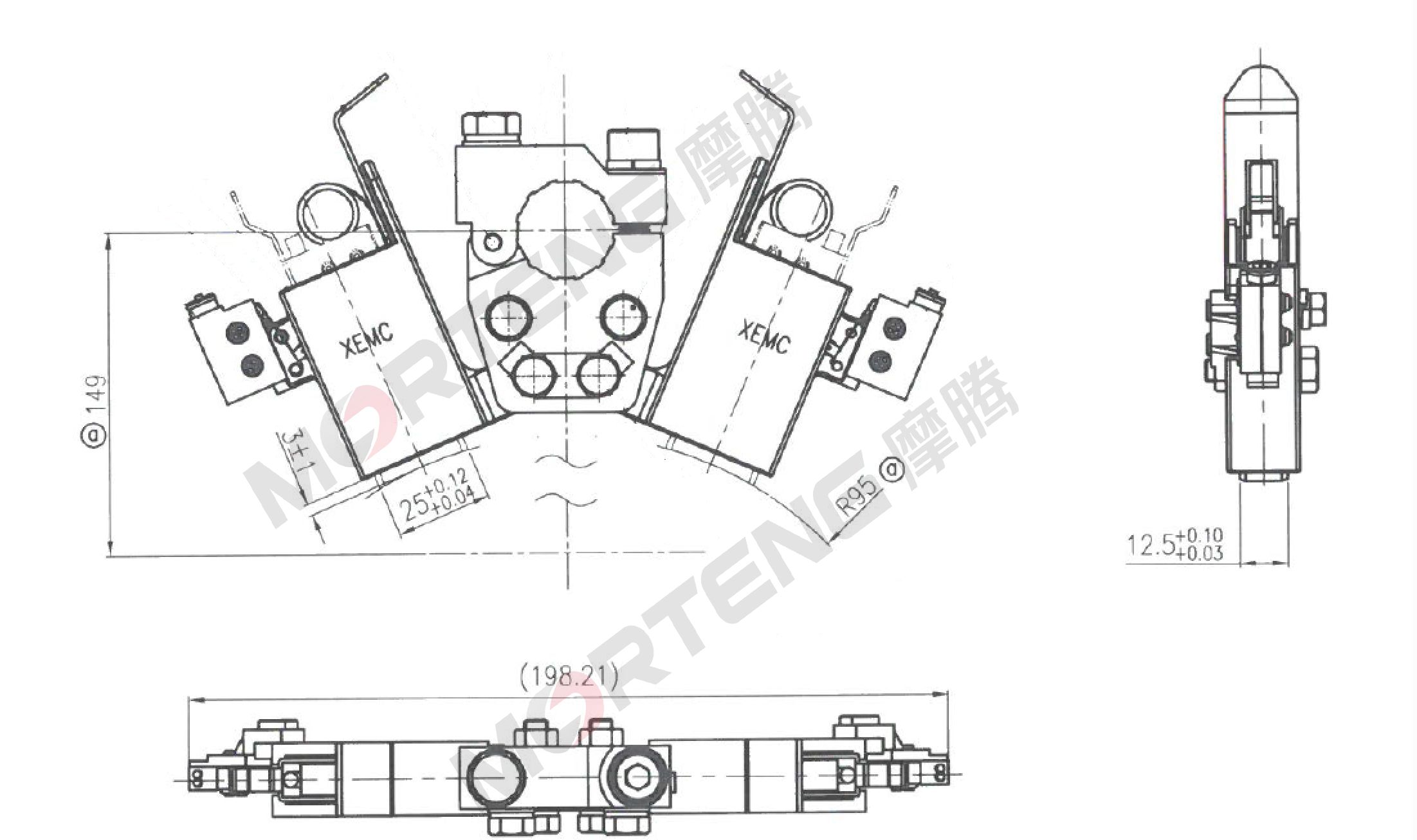

| Ibanga lezinto ezibonakalayo zokubamba ibhulashi: ZCuZn16Si4 《GBT 1176-2013 Cast ingxube yethusi nethusi》 | |||||

| Usayizi wephakethe | Usayizi wembobo yokukhweza | Ibanga lesikhungo sokufaka | Faka isikhala | Ububanzi bangaphandle bendandatho efanayo | Ubude Besibambi Sebhulashi |

| 12.5x25 | 25 | 149 | 3±1 | R95 | 198.21 |

Ungawagcina kanjani amabhulashi ekhabhoni

Umhlahlandlela wezinkinga zokulungisa ibhulashi le-carbon

Amakhasimende amaningi azobuza: Ngabe amabhulashi ekhabhoni adinga ukunakekelwa kanjani? Amabhulashi ekhabhoni adinga ukugcinwa isikhathi esingakanani? Ngabe amabhulashi ekhabhoni adinga ukushintshwa isikhathi esingakanani ngemuva kokusetshenziswa?

Incazelo enemininingwane yezinkinga zokulungisa ibhulashi lekhabhoni

1. Okokuqala, kufanele sakhe uhlelo lokulungisa ibhulashi le-carbon

Amabhulashi ekhabhoni agqoke izingxenye zezesekeli ze-electromechanical, okudingeka zishintshwe ezinyangeni ezingu-3-6 ngaphansi kwezimo ezivamile. Nokho, lesi isincomo setiyetha. Eqinisweni, imvamisa, isikhathi, nendawo yabasebenzisi abahlukene be-carbon brush kuhluke kakhulu. Lokhu kudinga abasebenzisi be-carbon brush ukuthi bakhe imvamisa yokulungisa amabhulashi ekhabhoni ngokuya ngokusetshenziswa kwabo. Isibonelo, uma zisebenza isikhathi eside, zidinga ukwandisa Imvamisa yokugcinwa kwebhulashi le-carbon, njengokuhlola kwamasonto onke ukuhlola isimo se-carbon brush, njll.

2. Okwesibili ukulandela ngokuqinile uhlelo lwesondlo

Abasebenzisi abaningi bebhulashi lekhabhoni benze uhlelo lokulungisa ibhulashi lekhabhoni eliphelele uma kuqhathaniswa, kodwa awenziwanga ngokuqinile. Ukuqina kanye nemvamisa yokuqaliswa kwangempela kwehliswa kakhulu.

Ngenxa yalokho, impilo yesevisi ye-carbon brush ifinyezwa kakhulu, futhi ngisho nokulimala okungavamile kwe-carbon brush noma indandatho yokuqoqa kubangelwa.

3. Amaphuzu okufanele unake lapho ugcina amabhulashi ekhabhoni

Okokuqala, kuyadingeka ukugxila ekugqokeni kwamabhulashi ekhabhoni futhi uqinisekise ukuthi ukugqoka amabhulashi ekhabhoni akudluli umugqa wokuphila. Kumabhulashi ekhabhoni angenawo umugqa wokuphila, ngaphansi kwezimo ezijwayelekile, amabhulashi ekhabhoni asele kufanele ashintshwe ngesikhathi lapho ukuphakama kwamabhulashi ekhabhoni asele kungu-5-10MM.

Okwesibili, ekugcinweni kwamabhulashi e-carbon, kuyadingeka futhi ukugxila ekuhlanzeni i-carbon powder kanye nokungcola kwezinto zangaphandle ukuze kugwenywe ukulimala ebusweni bendandatho yokuqoqa.

Ukwengeza, kuyadingeka futhi ukuhlola ukuthi ukulungiswa kwama-bolts wesibambi sebhulashi kukhululekile, futhi ngokuvamile wenze amamaki afanele ngemva kokugcinwa.

Okokugcina, kuyadingeka futhi ukuqinisekisa ukuthi kukhona ushintsho oluphawulekayo emandleni okunwebeka entwasahlobo noma amandla anwebekayo wekhoyili ye-spring pressure spring, noma ukubonakala komonakalo.

4. Uhlolojikelele lokugcinwa kwe-carbon brush

Ukufingqa, uma amaphuzu angenhla angafinyelelwa, i-carbon brush ingagcinwa kahle, engakwazi nje ukwandisa impilo yesevisi ye-carbon brush, kodwa futhi ivikele izesekeli ze-electromechanical ezifana nendandatho yokuqoqa emonakalweni. Uma abasebenzisi bebhulashi le-carbon benemibuzo ngenqubo yokusebenzisa ibhulashi lekhabhoni, ungashayela inombolo yethu yocingo ukuze ubonisane nganoma yisiphi isikhathi.

Inombolo yocingo: +86-21-6917 3552; 6917 2811; 6917, 3550-826